The Evolution of Calibration: Digital Calibration Certificates (DCC)

Digital Calibration Certificates (DCC) represent the future of calibration and offer numerous advantages over traditional “analog” calibration certificates. These digital documents address critical aspects associated with analog certificates, including manual management of measurement results, long-term preservation, and authenticity verification.

DCC Requirements:

- Long-Term Storage Utility:

- A DCC must be as useful as paper or paperless PDF certificates for long-term storage.

- Its digital structure should ensure information preservation over time.

- Machine Readability:

- A DCC must be machine-readable (M2M).

- This facilitates integration and process automation, enabling efficient communication between systems.

- Traceability to National Standards:

- The DCC must be directly or indirectly traceable to national standards.

- It should provide the same measurement result information as a current calibration certificate.

- Metrological Traceability Proof:

- The DCC must serve as a proof of metrological traceability.

- It should provide the same metrological information as a current calibration certificate.

- Inclusion of Additional Information:

- A DCC can contain additional data and metadata, such as result data points, numerical calibration curves, or any other evaluation information required by the customer.

- This flexibility allows customization based on specific needs.

- Use of Cryptographic Signatures:

- A DCC must use cryptographic signatures for security purposes:

- Integrity: Prevent unauthorized modifications to certificate data.

- Authenticity: Confirm the origin and authenticity of the certificate.

- If necessary, ensure confidentiality of sensitive data within the calibration certificate.

- A DCC must use cryptographic signatures for security purposes:

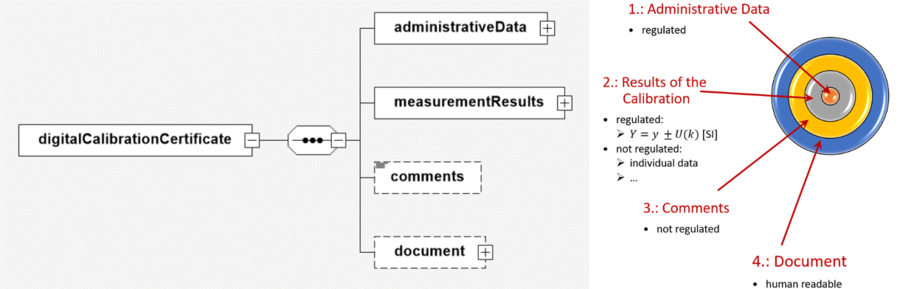

Digital File Structure and XML Format:

- DCCs are structured in an XML format, allowing standardized and machine-readable data management.

- This format supports integration with existing systems and ensures long-term data preservation.

- The hierarchical XML file structure includes administrative data, measurement results, and comments, organized for maximum clarity and accessibility.

Data Input and Schema:

- Within a DCC, input data follows a precise schema reflecting international standards such as ISO/IEC 17025.

- This schema ensures that each certificate contains all necessary information for calibration attestation, including measurement details, uncertainties, and utilized procedures.

- The XML structure makes these documents understandable for test and measurement machines, facilitating the reading of correction parameters in ATE and EOL measurements.

Digital Signatures:

- A fundamental aspect of DCCs is the ability to apply a digital signature, ensuring authenticity and data integrity.

- The digital signature confirms that the certificate originates from an accredited laboratory and that the data remains unaltered.

DCCs represent an advanced solution that surpasses the limitations of analog certificates, offering a safer, more reliable, and internationally compliant approach to calibration documentation.